BOC EDWARDS ZENiTH Abatement system

BOC EDWARDS ZENiTH Abatement system

$2,950 (USD)

Location:Santa Barbara, CA

or

Call 805-895-7767

Description

DESCRIPTION:

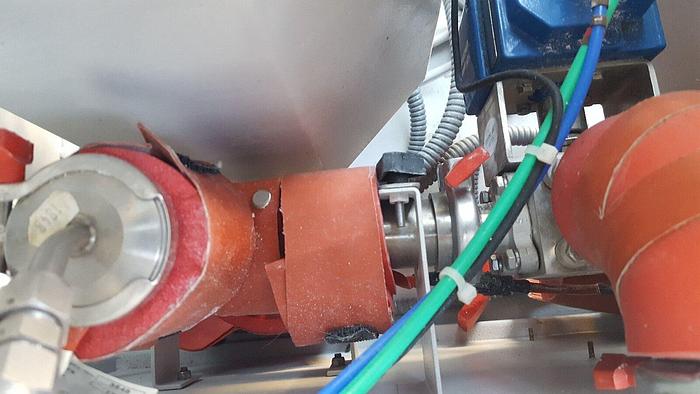

BOC

EDWARDS ZENiTH Abatement system

The

Zenith integrated vacuum and abatement systems from Edwards

offer a range of turn-key, process-centric

exhaust management solutions for semiconductor manufacturing. All components

are completely integrated and each function is supported by a powerful control

interface.

The

iXH series of dry pumps for harsh processes feature a wide temperature range,

which helps minimize by-product accumulation. The Gas Buster and pump seal

technology helps lengthen process life and reduce leakage risks.

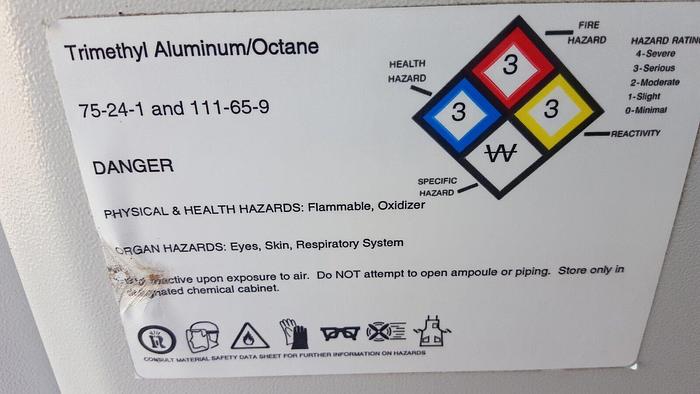

The

Atlas combustion-based abatement family offers a range of abatement systems

tailored to the needs of individual semiconductor manufacturing processes, such

as CVD and etch. A combination of combustion abatement and wet scrubbing stages

provide excellent powder handling and resistance to corrosion.

Mike

Allison, managing director, sales and service, Edwards said: Advanced

semiconductor manufacturing processes have created new vacuum technology

challenges, while environmental concerns are leading to tighter regulation of

the gases exhausted during the semiconductor manufacturing process. At the same

time, economic imperatives are driving semiconductor manufacturers to seek

opportunities to lower the CoO of their tools, as well as reduce overall manufacturing

costs. Both the Atlas abatement system and the iXH pump were designed to meet

these latest manufacturing requirements, while delivering lower system CoO,

reduced utility costs, improved ease-of-use and extend maintenance cycles.

Combining the two in a Zenith system, results in additional CoO benefits from

increased system integration, while also reducing installation time and

complexity, and saving valuable fab real estate.

System was de-installed in working operational condition. All returns must comply with stated Return Policy. Please continue:

PAYMENT OPTIONS:

We accept Paypal, Company Check, Wire Transfers.Please call (805) 895 7767

TAXES & FEES:

California Sales Tax applies if order within California at 8%. Handling charges may apply. Your cost is the price of your item, shipping/handling charge, insurance, and sales tax if applicable.

REFUNDS& RETURNS

:

No returns after 14 days. Returns must have good reason for return, i.e. defective items, missing items, or items not described accurately.Returned items must be in same condition as shipped for refund.PLEASE Contact before leaving Negative Feedback in the seller review.

Please Contact for any other specific heavy machinery or scientific instrument related inquiries, (have a database full of market contacts with varying industrial machinery and components, and can most likely get whatever you need). Please Message for all other Inquires, THANK YOU & HAVE A GOOD DAY!

IF THERE ARE ANY PROBLEMS WITH THE ITEM DO NOT TRY TO REPAIR AND INVESTIGATE.

CONTACT US IMMEDIATELY.

WARRANTY IS NULL VOID IF ANY ITEM IS TAMPERED WITH, OPENED OR DISASSEMBLED.

WE HAVE SEVERAL WAREHOUSES.

Please check with us about ITEM'S AVAILABILITY prior to ordering.

UPON RECEIPT OF YOUR PURCHASE PLEASE PHOTOGRAPH, DOCUMENT,

AND SAVE ALL PACKAGING WHETHER DAMAGE IS VISIBLE OR NOT. ALL CLAIMS MUST BE

REPORTED AND ACKNOWLEDGED WITHIN 72 HRS OF RECEIPT.

Specifications

| Condition | Used |

| Mike allison, managing director, sales and service, edwards said | Advanced semiconductor manufacturing processes have created new vacuum technology challenges, while environmental concerns are leading to tighter regulation of the gases exhausted during the semiconductor manufacturing process. At the same time, economic imperatives are driving semiconductor manufacturers to seek opportunities to lower the CoO of their tools, as well as reduce overall manufacturing costs. Both the Atlas abatement system and the iXH pump were designed to meet these latest manufacturing requirements, while delivering lower system CoO, reduced utility costs, improved ease-of-use and extend maintenance cycles. Combining the two in a Zenith system, results in additional CoO benefits from increased system integration, while also reducing installation time and complexity, and saving valuable fab real estate. |